Automation is playing an increasing role throughout industry in Ireland and beyond as businesses adopt Industry 4.0-based practices. When it comes to addressing the various layers of integration within a typical factory automation system, understanding the industrial automation pyramid is crucial and how Industry 4.0 is starting to change it. With this challenge in-mind, the AMTCE is delighted to announce The Industry 4.0 Automation Pyramid Technologies programme.

Responding to the rapidly-changing needs of the Irish manufacturing sector, the AMTCE has added a new programme of online learning courses which will aim to upskill businesses in this increasingly vital area.

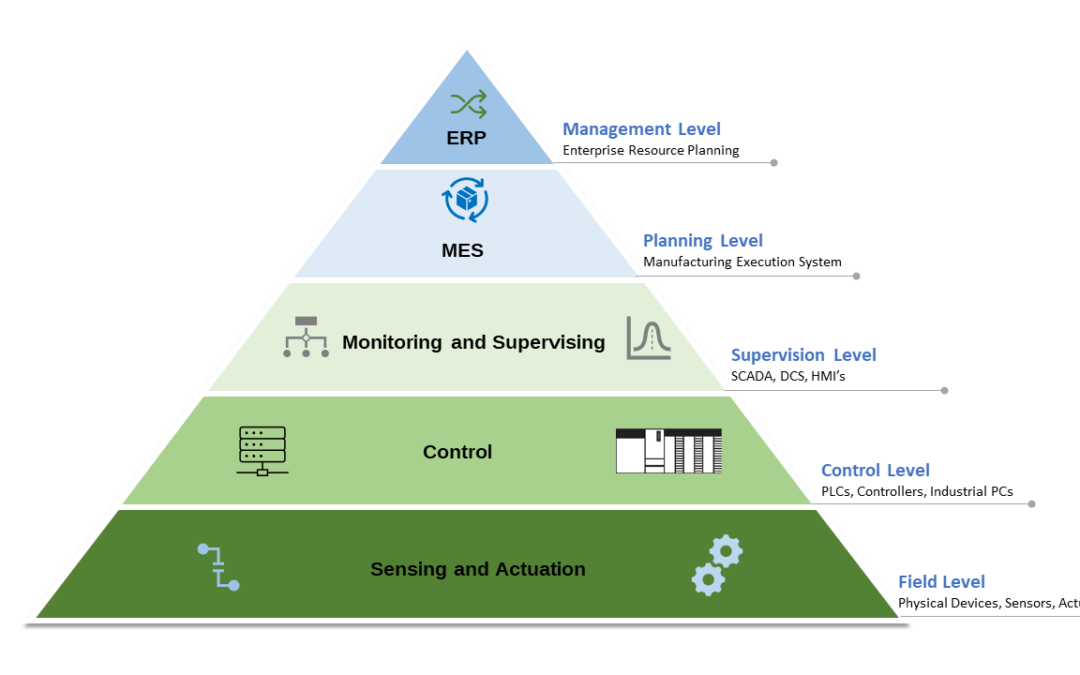

What is the Industrial Automation Pyramid?

The industrial automation pyramid represents the various layers of integrated automation that comprise a typical factory automation system. The layers integrate and interoperate with each other vertically through industrial communications. A typical automation pyramid comprises 5 distinct layers:

1. Field Level (Physical Devices, Sensors, Actuators)

2. Control Level (PLCS, Controllers, Industrial PCs)

3. Supervision Level (SCADA, DCS, HMI’s)

4. Planning Level (Manufacturing Execution System (MES))

5. Management Level (Enterprise Resource Planning (ERP)

In many cases, the actual structure of the automation pyramid can be widely varied. For instance, levels 0 and 5 in some pyramids may not exist separately, and in other cases, various levels may be categorised in the one level.

The Rise of Automation Pyramid Technologies

The adoption of Industry 4.0 will have a significant impact architecturally on automation systems. Increased vertical integration between the layers will flatten the pyramid driven by the adoption of IP-based networks which enables direct office to factory floor connectivity. Meanwhile, the provision of ubiquitous connectivity (wired/wireless) between processes, devices, equipment, products, organizations etc. is a key element of industry 4.0 driven automation.

There is also increased horizontal integration to enhance end-to-end connectivity and improve information flows. For machine-to-machine (M2M) communications, the Industrial Internet of Things (IIoT) is playing an increasingly central role, coupled with a strong focus on the provision of data and data processing in the form of machine learning to improve operational efficiency and reliability.

The AMTCE’s Industry 4.0 Automation Pyramid Technologies programme focuses on layers 1-3 of the automation pyramid and comprises of 13 online interactive courses including text and images, in addition to a wide range of animations to provide the learner with a detailed knowledge on:

- Introduction to industrial automation;

- Principles of pneumatics;

- Introduction to electricity;

- DC electricity;

- AC electricity;

- Solid state;

- Introduction to wiring;

- Introduction to electric motors;

- Sensor technologies;

- Programmable controllers;

- Process controls;

- Hydraulics /electrohydraulics; and

- Robotics.

Each chapter ends in a TEST, validating knowledge acquisition. Once all course chapters have been completed, the user receives an SMC Certificate.

Register Your Interest Now

The AMTCE has attracted a significant amount of interest in this learning programme and fully recommends early registration to avoid disappointment. To ensure your place in the programme, register your interest now.